Optimizing the supply chain: one rice ball at a time

NewsPicks|2024-2-26

5 minute read

A supply chain refers to the sequence of events from the procurement of raw materials and parts to the sale of a product.

From a consumer's point of view, there don’t seem to be any issues when receiving a quick delivery from an e-commerce site or when seeing a shelf in a convenience store full of products. But behind this “partial convenience” – more on that later – lie a variety of inefficiencies and challenges.

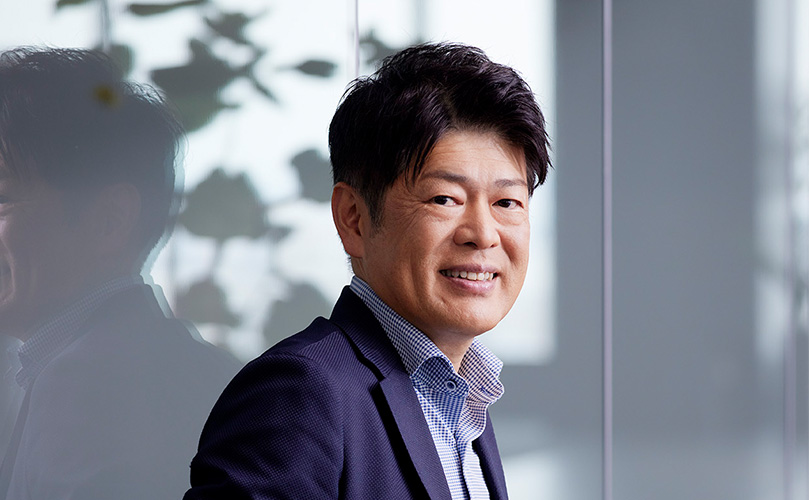

Shunichi Ko, head of the cross-industry solutions division of the Fujitsu Global Business Solutions Business Group, is trying to solve supply chain problem. "The technology is already there. All we have to do is put it into practice." he emphasizes.

How can we optimize the entire supply chain in a world where physical objects are difficult to digitize? Ko explains.

## Where did the product come from?

-In recent years, we have heard a lot about supply chain disruptions due to unforeseen events such as the pandemic and natural disasters, as well as logistics crises due to driver shortages. What is your take on the current state of supply chains?

Ko: My honest feeling is, "Why aren’t we acting now?" None of the supply chain challenges you just mentioned have come out of the blue recently. Over the past 10 years, there have been various inefficiencies, but little has been done to resolve them.

I want to do something about this situation.

-What kinds of inefficiencies do you see, specifically?

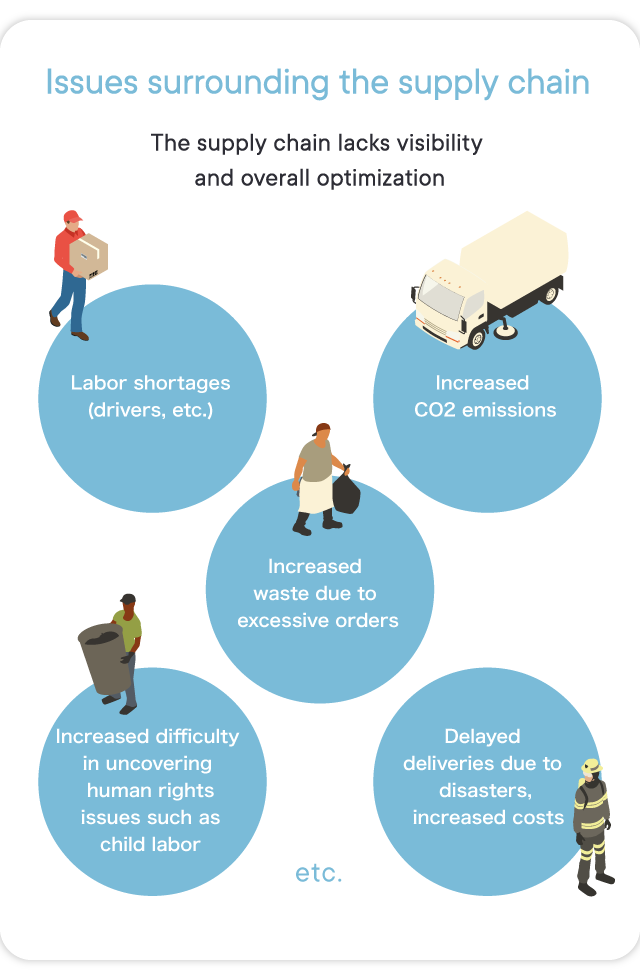

For starters, consumers and even many companies don't have a complete picture of the supply chain. A prominent example is the issue of child labor and forced labor, which has been a sore point for the apparel industry for several years. This is due to a lack of a mechanisms for clothing manufacturers and retailers to track the process of where and by whom raw materials are produced and under what circumstances they are manufactured and processed.

-On the other hand, for a consumer, it's very convenient to order something from Amazon and receive it the next day. The supply chain just seems to work.

It’s true that from a consumer's point of view, it may look like a very well-designed mechanism. But that's just a single type of partial optimization, and not a total optimization across the supply chain. I buy things online, too, but sometimes I forget about the next-day delivery, and there’s nobody home to pick it up. From my point of view, it’s convenient because I can have it redelivered immediately, but for the delivery service, it’s extremely inefficient and leads to an increase in CO2 emissions.

-So, consumer convenience is creating inefficiencies.

Right. Onigiri [rice balls that are popular in Japan] are available on convenience store shelves around the clock. But that’s because stores order more than they need to satisfy demand so they can promote the “partial convenience” of having onigiri available all the time. As a result, tons of unsold items get tossed out when they pass their expiration date.

And considering all the natural disasters we’ve gone through recently, strengthening the resilience of supply chains is critical. Even in Japan, transportation routes are often cut off due to earthquakes, floods, etc., which impedes logistics. You’ll recall that when the COVID-19 pandemic brought factories and logistics to a standstill, it was impossible to keep up with the manufacture and delivery of goods.

Visualization and optimization of the entire supply chain is essential for flexibly responding to unforeseen circumstances.

## The technology is here. All we have to do is execute.

-What are the challenges to changing the way supply chains work?

Ko: There are many factors, but the lack of data integration and visualization is a big problem. The supply chain now extends globally across countries and regions, creating a complex structure involving diverse stakeholders. So the data applied to raw materials and products can easily become siloed, and accuracy and granularity vary between suppliers. It’s not possible to optimize the whole system under these conditions.

Data integration and visualization are fundamental for reforming the supply chain.

-But isn't it technically very difficult to achieve visualization and optimization in something as complex and large as a supply chain?

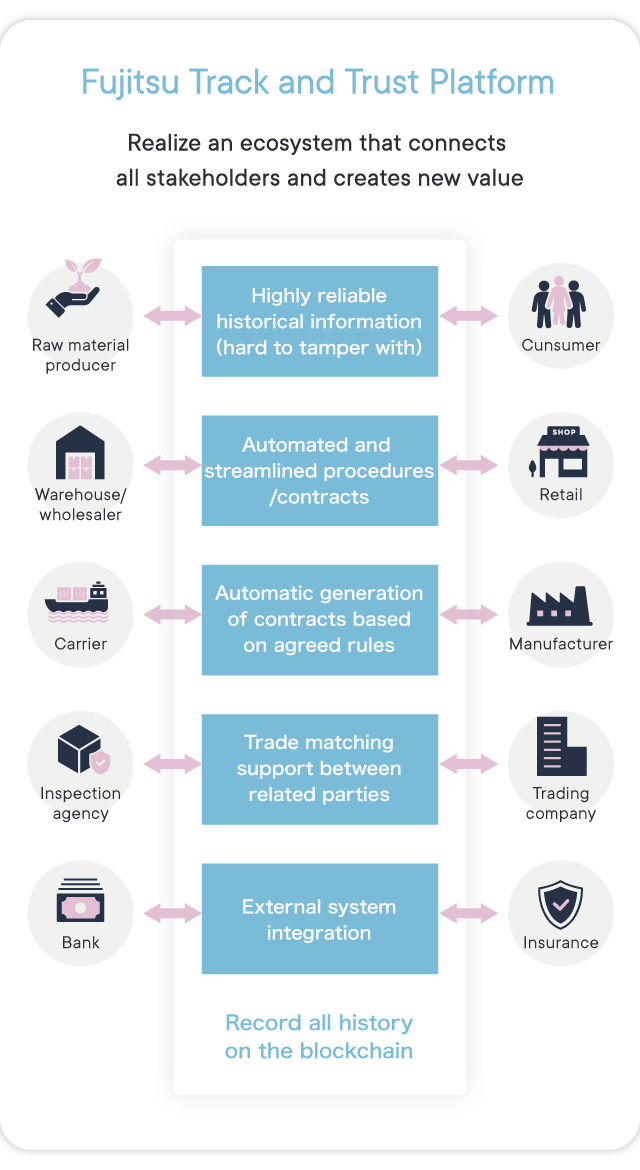

Ko: Just so there’s no misunderstanding, I want to say loud and clear that we already have the technology to optimize the supply chain. Data can be stitched together on a platform with accuracy and granularity, and visualized securely so that it can’t be tampered with. We can do this with technologies that already exists, such as blockchain and image analysis. The reason I can say that with confidence is that Fujitsu offers a solution that does just that.

-So how can Fujitsu solutions really be put into practice?

Ko: As we've discussed, there are many aspects of the supply chain that require a variety of technologies for different purposes, from data visualization and integration to supply/demand forecasting and disaster forecasting. I think Fujitsu's strength is that we have offerings that cover all of these areas.

The foundation is Fujitsu Track and Trust, a digital platform that ensures supply chain transparency and reliability. Blockchain technology, which Fujitsu was among the first to adopt, makes the supply chain transparent by connecting information generated in a series of processes, from the production and procurement of raw materials to in-store sales.

We also offer a variety of solutions based on this platform. For example, we have solutions that can reduce the disposal of products such as rice balls by using AI technology to predict supply and demand. We also provide services to visualize CO2 emissions in the supply chain.

Fujitsu also has a supercomputer that can predict the occurrence of linear precipitation bands that cause disasters dues to heavy rain. By comparing this forecast data with data, such as the difference in elevation of the ground surface from satellite images, it’s possible to predict when and where roads will become flooded.

That information can be relayed to truck drivers, enabling them to transport goods while avoiding these routes.

The combination of Fujitsu's full range of technologies enables vast amounts of data scattered across the supply chain to be quickly and accurately processed, facilitating management and analysis on the same platform. This is Fujitsu’s advantage.

- Do you have any real business use cases?

One of the latest examples is "tex.tracer" developed in collaboration with apparel companies for the fashion industry. This solution visualizes the process of clothing reaching consumers, from raw material producers to processing manufacturers to logistics and distributors, allowing apparel brand owners to trace the social and environmental impact of their supply chain.

In the food industry, we are working with Belgian beer company AB InBev to solve similar challenges. By integrating and visualizing data on our platform from stakeholders involved in beer production and sales, including barley growers, breweries, warehouses, and carriers, resources like water and energy can be used more efficiently during the production process.

In both cases, consumers can scan a QR code on a product to see who manufactured the product, how, and with what materials.

Sharing supply chain information with consumers can also improve the brand value of a company or product. For example, a beverage company could market juice made out of discarded fruit that still tasted good but was misshapen.

In this way, addressing supply chain issues not only reduces the negative impact to zero, but also produces positive effects such as the development of new value-added goods and services.

## Dilemma between Solving Social Issues and Balancing Business

- While technology has dramatically increased the range of possibilities, there are still many challenges. What do you still find difficult?

Ko: We still have to make a profit since this is corporation. Striking a balance between business and solving social issues is really difficult and perplexing.

One particular event that brought that home to me. In 2022, Fujitsu conducted a proof-of-concept trial to bring about a decarbonized society in collaboration with British power companies and others. We connected data about the operation and charging of electric vehicles that deliver food and beverages with data about the CO2 emissions of electricity used. That let us visualize the best times and locations to charge EVs in order to reduce CO2 emissions and provide results to milk delivery companies. As a result, the company was able to reduce CO2 emissions from EV charging by 15%.

We pride ourselves on the significance of this proof-of-concept, but there's a higher barrier for selling this system as a service.

The majority of food and beverage delivery companies are small and medium enterprises, which do not have the capacity to pay high costs just for decarbonization efforts. Even though we know we can help solve societal problems, we can’t run our business without companies willing to pay. It's a tremendous dilemma.

-What drives you to keep working on transforming the supply chain?

Ko: The answer is simple. My motivation is to do something really good for the world.

When I first joined Fujitsu, I was involved in semiconductor development. At that time, the Japanese economy was growing rapidly, and our company was building new factories to manufacture and sell huge numbers of semiconductors. The number of home appliances and electronic devices that required semiconductors was increasing rapidly, and we sold as many as we could make. It certainly made people's lives more convenient. But when I think about whether it was good for society and the environment, I can't say yes. Looking back now, there’s no doubt that the business model of mass production and mass consumption put a burden on the environment.

Meanwhile, I started a family and began asking myself, "What's really important?" When my children asked me what I did for a living, I wanted to hold my head up high and say, "I'm doing great things for the world."

Fortunately, now I'm in a position to use digital technology to address societal issues. And I couldn’t be happier to contribute to building a sustainable society with technologies originating in Japan, starting with Fujitsu. I’m going to keep working to build that future and transform the supply chain.

2023/11/6 NewsPicks Brand Design

Writer:Arika Tsukada

Desinger:Kimie Tanaka

Photographer:Masahiro Kojima

Editor:Asuka Kanai

We have obtained permission from our company to publish the content that was covered and featured in NewsPicks Brand Design.

Shunichi Ko

SVP / General Manager of Cross Industry Solution Business Unit, Fujitsu

Shunichi Ko began his journey with Fujitsu Limited in 1991. Within the Electronic Device Division, he played a pivotal role in the global standardization of automotive networks, including CAN, LIN, FlexRay, and the automotive OS (AUTOSAR). He also contributed significantly to functional safety. From 2012 onwards, Ko has been at the forefront of Mobility PF/Digital Transportation and Trusted Society initiatives, addressing the market’s pivot towards IoT and connected vehicles. He assumed his present role in April 2023.

Sustainability Transformation for prosperity

What is a digital society, and why do we need it?

Featured insights

Prosperity:

Developing a digital society

Balancing business goals with the environment: A planet full of opportunities

Convenience and well-being at all ages: A digital leap to a fulfilling life